It wasn’t the first time someone had the idea. Serious cyclists have been locking up their bikes outside coffee shops with helmet straps or other bizarre methods with no security for years. What was different this time was the passion for a real solution. Serious cyclists have been locking their bikes outside cafes for years with helmet straps or other bizarre methods with no security. What was different this time was the passion for a real solution.

I met Jacob Rathe in February 2015 at Stumptown Coffee in Portland, Oregon, and he was stuck. He’d tried for years to bring his “Omloop” lock concept to reality with a few crude prototypes, but realized it was no small chore. New Product Development requires more expertise and capital than meets the eye. Personally, after 30 plus years of training and racing bikes, I had never bought a bike lock. But maybe this was the bike lock I finally needed, and I could figure out some way to launch the product through my new brand, OTTO. Jacob and I agreed to give it a try, and I vividly remember him saying “All I want is a few prototypes for me and my buddies.” He had tried for years to turn his “Omloop” lock concept into reality with a few rough prototypes, but realized it was no easy task. The development of new products requires more know-how and capital than meets the eye. Personally, after more than 30 years of training and road cycling, I had never bought a Bike Lock. But maybe this was the Bike Lock I finally needed, and I could find a way to bring the product to market through my new brand, OTTO. Jacob and I decided to give it a try, and I distinctly remember him saying, “I just want some prototypes for me and my buddies.”

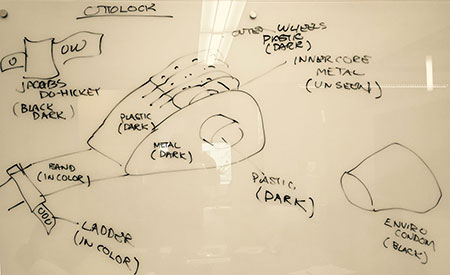

About a month later, Jacob and I met with a whiz engineer, and we started playing around with strip steel, soon realizing you couldn’t cut a thin steel band with bolt cutter jaws due to the aspect ratio. “OTTOLOCK” was born, and after a few more turns we decided to bring a sketch and a band sample to Interbike 2015 to see what people thought. Our good friend Tory Orzek helped out with some industrial design to smooth out some prototype edges, and we were rolling. Before taking off for Vegas, I remember Tory saying, “You really should put this on Kickstarter. It’s great, and you’ll sell zillions.” “OTTOLOCK” was born, and after a few more tries, we decided to bring a sketch and a tape sample to Interbike 2015 to see what visitors thought. Our good friend Tory Orzek helped us smooth out the edges of the prototype and we were off. Before we left for Las Vegas, Tory said, “You guys should really put this on Kickstarter. It’s great and you’ll sell it a zillion times over.”

The response at Interbike was so positive that we leapt into action to finish the design. Even with sound engineering rigor, we were a bit naive about all of the potential lock failure modes. Because our goal was an extremely lightweight form factor, we actually thought we could achieve success with a plastic lock head. That idea lasted one 3-pound hammer test. All said and done, we iterated the lock with eight major revisions to get to our current production specs. Despite our solid engineering skills, we were somewhat naïve about the possible modes of failure of the lock. Since our goal was an extremely lightweight form factor, we actually thought we could succeed with a plastic lock head. This idea survived a 3-pound hammer test. All in all, we revised the lock eight times to arrive at our current production specifications.

A highlight of the design process occurred during the Kickstarter shoot in August 2016, down on the Tilikum Crossing bridge in Portland where we were interviewing random cyclists and potential customers. We were confident in our design, but a former thief actually broke the lock band – on camera, and much to my surprise. He used a simple twisting trick, and I had a serious “oh crap” moment. The team rallied hard as our campaign was starting in just three weeks, and we introduced Kevlar® as the additive solution. This part of the story illustrates our never-give-up passion. We were convinced of our design, but a former thief actually broke the closure band – on camera and much to my surprise. He used a simple twisting trick, and I had a serious “oh crap” moment. The team rallied hard as our campaign was starting in just three weeks, and we introduced Kevlar® as the additive solution. This part of the story illustrates our never-give-up passion. The team pulled together as our campaign began in just three weeks, and we introduced Kevlar® as an add-on solution. This part of the story illustrates our passion to never give up.

Many, many more individuals all worked together to build samples and our Kickstarter program including focus groups, videographers, photograpers, copywriters, graphic designers, testers, PR folks, and more. This was a great exercise in team collaboration and continual improvement, all directed towards our September launch date. That first day was amazing; all of us were riveted to our screens. We exceeded our crowd funding goal in under 24 hours and collectively watched our product vision become reality. At the end of 30 days, with 4,000 backers on the team, we knew we had something special and that we’d better get to work to deliver on our promise. This was a great exercise in team collaboration and continuous improvement in anticipation of our September launch date. The first day was fantastic; we were all glued to our screens. We surpassed our crowdfunding goal in less than 24 hours and watched together as our product vision became a reality. At the end of 30 days, with 4,000 supporters on the team, we knew we had created something special and that we had better get to work delivering on our promise.

The last six months in OTTO have been crazy good with so many details to get just right before this really takes off. And here we are today: with a committed supply chain of U.S. suppliers; with our own final assembly line; and a new business for OTTO with so much opportunity ahead. And here we are today: with a dedicated supply chain of U.S. suppliers, with our own final assembly line, and a new business area for OTTO that offers so many opportunities.

OTTOLOCK is a story of vision, teamwork, flexibility, and grit. I am so proud of our team and many partners. I am so proud of our team and many partners.

– Jake VanderZanden